About

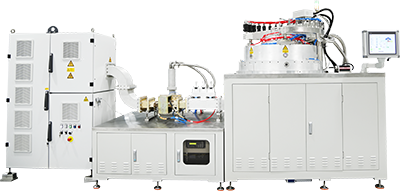

Chengdu Wattsine Electronic Technology Co.,Ltd is a national high-tech enterprise located in Chengdu, China, focusing on the application of microwave/RF and high-frequency power energy, engaged in R&D, production and sales of solid-state power generators based on semiconductor devices and high-frequency, high-power technology, provides solutions and technical services for RF energy applications in ISM field.

Products

Applications

In the semiconductor field, Wattsine power generators are one of the key components of the front-end process machines for thin film deposition, etching, ion implantation and cleaning.

Photovoltaic is one of the core areas in the construction of new energy power generation, RF power generators of Wattsine have been widely used in it

power generators of Wattsine have been widely used in the field of particle accelerators, mainly including synchrotron light sources, XFEL, CIADS and others.

Wattsine microwave power generator can be used in the preparation of carbon-based materials, including CVD diamonds, industrial abrasives and tools, diamond thermal conduction and heat dissipation materials, diamond optical window materials and os.

Wattsine microwave power generator can be used in the medical field, mainly in medical accelerators, ablation, thermotherapy, microwave physiotherapy, plasma beauty and others

Wattsine microwave sources (microwave generators) are suitable for industrial applications, mainly in microwave heating, microwave drying, microwave blanching, microwave defrosting, microwave lighting, microwave curing, microwave sintering, and other areas.

News

![]()

![]()

Wattsine News channel provides real-time updates on Wattsine announcements, honors and latest events.

Industry information channel mainly updates the latest international and domestic industry information related to Wattsine products.

CVD Encyclopedia

Industry Encyclopaedia

Support

Chengdu Wattsine electronic to provide a full range of pre-sales service, for you to solve all the concerns related to our products... Pre-sales hotline 028-85964177

All our customers will experience the high-quality after-sales service provided by WATTSINE after purchase our products...

Here you will find a collection of Frequently Asked Questions (FAQs) about our products before and after the sale of Wattsine...

Related videos about Wattsine