Application Overview

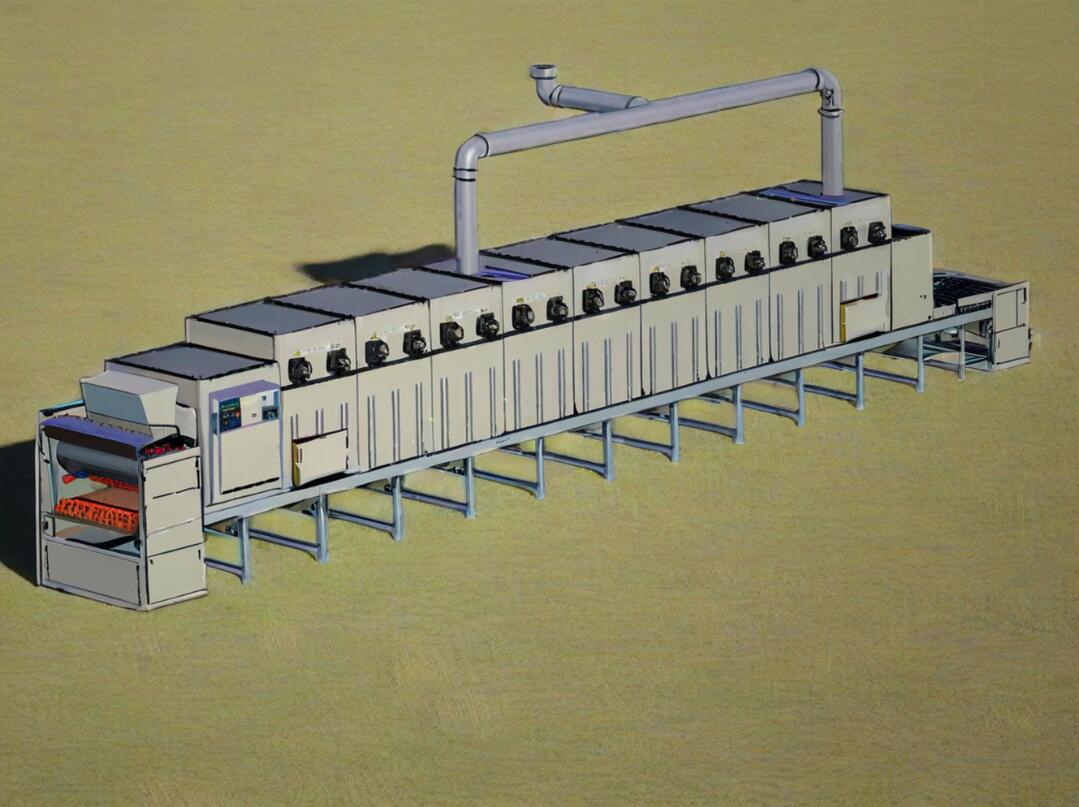

The core component of microwave drying equipment is the microwave generator. Currently, microwave drying primarily operates at a frequency of 2450 megahertz. It is widely employed for drying applications across industries such as chemicals, foodstuffs, agricultural by-products, timber, building materials, and paper products. Additionally, it can be utilised for sterilisation purposes in foodstuffs and agricultural by-products.

Application Details

Microwave drying technology is a process that utilises microwave energy to directly interact with polar molecules within materials (such as water molecules). This interaction causes the molecules to absorb microwave energy and convert it into thermal energy, thereby achieving material heating and drying. The microwave energy is generated by a microwave generator.

Wattsine solid-state microwave generators (microwave sources) offer multiple advantages when applied to microwave drying.

Firstly, in terms of drying speed, the microwaves generated by Wattsine solid-state microwave generators penetrate deep into the material. This causes water molecules within the material to vibrate rapidly, generating heat through friction. This heating method, working from the inside out, enables moisture within the material to evaporate swiftly, significantly accelerating the drying process. Compared to traditional drying methods, microwave drying requires substantially less time.

Secondly, it delivers excellent drying uniformity. Microwaves emitted by the Wattsine Solid-State Microwave Generator distribute relatively uniformly within the drying chamber, allowing all parts of the material to absorb microwave energy evenly. This achieves consistent drying, which is crucial for ensuring the quality of the dried material and avoids the potential issues of localised over-drying or under-drying that can occur with traditional drying methods.

Moreover, the Wattsine solid-state microwave generator exhibits strong selectivity during drying. Microwaves primarily act upon polar molecules within the material, such as water molecules, while minimally affecting other constituents. This enables effective moisture removal while maximising the retention of the material's active components. It is particularly suitable for drying materials requiring high component stability, such as traditional Chinese medicinal herbs and foodstuffs.

In terms of energy efficiency, the Wattsine solid-state microwave generator also excels. Due to the rapid drying speed of microwaves, drying tasks can be completed within a shorter timeframe. This reduces energy losses associated with prolonged drying processes, enhances energy utilisation efficiency, and proves more energy-efficient compared to some traditional drying methods.

Additionally, microwave source drying offers superior controllability. By adjusting parameters such as power and frequency on the Wattsine solid-state microwave generator, the intensity and speed of drying can be precisely controlled to suit the requirements of different materials. This capability for precise control is crucial in industrial production for ensuring consistent product quality.

Finally, microwave drying technology also offers certain environmental advantages. It does not require the use of large volumes of hot air or other drying media, as seen in some traditional drying methods, thereby reducing environmental impacts such as exhaust emissions.

Wattsine solid-state microwave generators (microwave sources) offer multiple advantages when applied to microwave drying.

Firstly, in terms of drying speed, the microwaves generated by Wattsine solid-state microwave generators penetrate deep into the material. This causes water molecules within the material to vibrate rapidly, generating heat through friction. This heating method, working from the inside out, enables moisture within the material to evaporate swiftly, significantly accelerating the drying process. Compared to traditional drying methods, microwave drying requires substantially less time.

Secondly, it delivers excellent drying uniformity. Microwaves emitted by the Wattsine Solid-State Microwave Generator distribute relatively uniformly within the drying chamber, allowing all parts of the material to absorb microwave energy evenly. This achieves consistent drying, which is crucial for ensuring the quality of the dried material and avoids the potential issues of localised over-drying or under-drying that can occur with traditional drying methods.

Moreover, the Wattsine solid-state microwave generator exhibits strong selectivity during drying. Microwaves primarily act upon polar molecules within the material, such as water molecules, while minimally affecting other constituents. This enables effective moisture removal while maximising the retention of the material's active components. It is particularly suitable for drying materials requiring high component stability, such as traditional Chinese medicinal herbs and foodstuffs.

In terms of energy efficiency, the Wattsine solid-state microwave generator also excels. Due to the rapid drying speed of microwaves, drying tasks can be completed within a shorter timeframe. This reduces energy losses associated with prolonged drying processes, enhances energy utilisation efficiency, and proves more energy-efficient compared to some traditional drying methods.

Additionally, microwave source drying offers superior controllability. By adjusting parameters such as power and frequency on the Wattsine solid-state microwave generator, the intensity and speed of drying can be precisely controlled to suit the requirements of different materials. This capability for precise control is crucial in industrial production for ensuring consistent product quality.

Finally, microwave drying technology also offers certain environmental advantages. It does not require the use of large volumes of hot air or other drying media, as seen in some traditional drying methods, thereby reducing environmental impacts such as exhaust emissions.