Application Overview

With the continuous advancement of microwave sintering technology, solid-state microwave generator are gradually emerging as a key factor driving progress in this field.

Application Details

A microwave generator is essentially a device capable of generating microwaves. Its core operating principle is based on knowledge of electronics and electromagnetism. Microwaves generated by such sources possess distinct advantages. Firstly, they offer high efficiency, penetrating directly into material interiors to achieve uniform heating throughout the substance. This contrasts with conventional heating methods where heat gradually propagates from surfaces inward, significantly reducing processing times. Secondly, they enable selective heating: different materials exhibit varying microwave absorption capacities, allowing sources to target heating precisely according to material properties. This facilitates the sintering of diverse material types.

Solid-state microwave generator represent a novel development in recent years. Compared to magnetrons, they offer superior stability, adjustability, and reliability. These sources enable precise control over microwave parameters such as frequency, power, and phase, allowing flexible adaptation to the sintering requirements of diverse materials. Let us now explore the application advantages of solid-state microwave sources in microwave sintering.

Precise Control

Solid-state microwave generator exhibit exceptional precision in control capabilities. Compared to traditional magnetron microwave generator, they enable precise adjustment of output microwave power, frequency, and phase. Through advanced electronic control systems, real-time monitoring and precise adjustment of microwave parameters are achievable.

During microwave sintering, precise parameter control enables the customisation of optimal sintering processes tailored to the characteristics and requirements of different materials. For instance, with materials highly sensitive to temperature and heating rates, solid-state microwave generator can precisely regulate microwave power to achieve slow, uniform heating. This prevents issues such as cracking or deformation caused by excessive temperatures or rapid heating rates.

High Stability

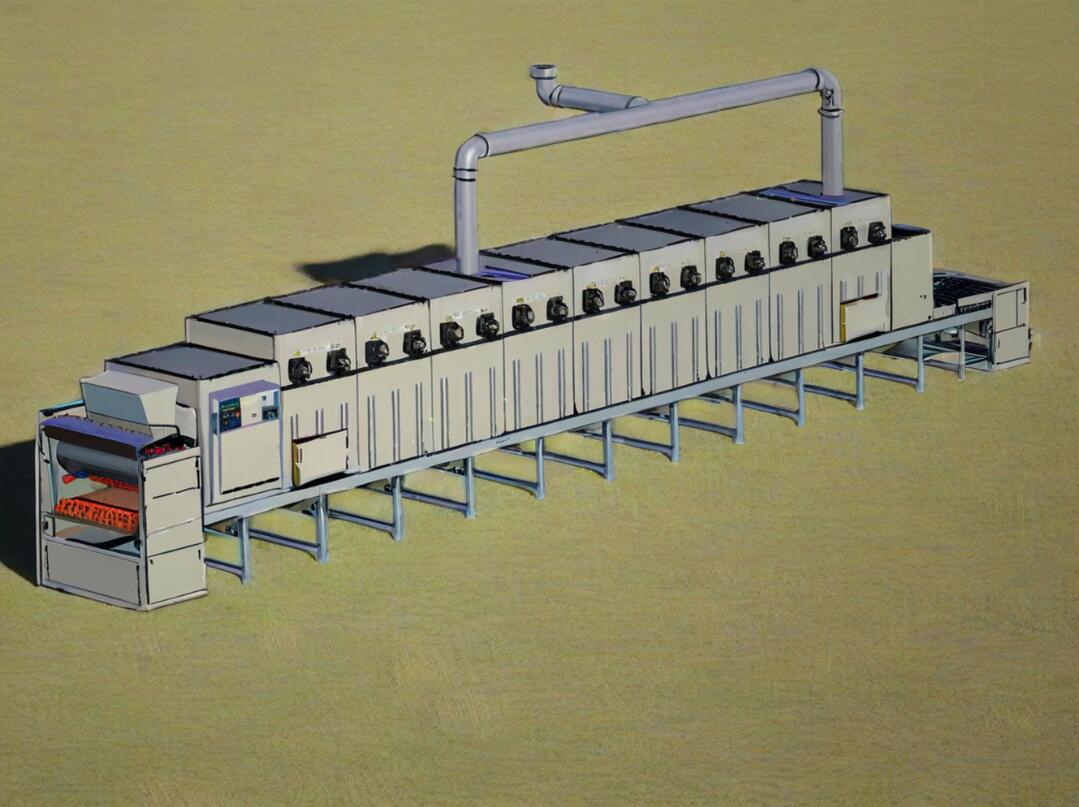

Solid-state microwave generator exhibit exceptional stability. Based on semiconductor technology with relatively simple internal structures, they lack the wear-prone components found in magnetrons. This enables highly stable microwave power and frequency output during prolonged operation.

In continuous microwave sintering production, stability is paramount. Consistent microwave output ensures repeatability and uniformity in the sintering process, thereby enhancing product quality and yield rates. For instance, in the mass production of ceramic cutting tools, employing solid-state microwave generator guarantees that each tool undergoes sintering under identical microwave conditions, ensuring stable tool performance and quality.

Solid-state microwave generator represent a novel development in recent years. Compared to magnetrons, they offer superior stability, adjustability, and reliability. These sources enable precise control over microwave parameters such as frequency, power, and phase, allowing flexible adaptation to the sintering requirements of diverse materials. Let us now explore the application advantages of solid-state microwave sources in microwave sintering.

Precise Control

Solid-state microwave generator exhibit exceptional precision in control capabilities. Compared to traditional magnetron microwave generator, they enable precise adjustment of output microwave power, frequency, and phase. Through advanced electronic control systems, real-time monitoring and precise adjustment of microwave parameters are achievable.

During microwave sintering, precise parameter control enables the customisation of optimal sintering processes tailored to the characteristics and requirements of different materials. For instance, with materials highly sensitive to temperature and heating rates, solid-state microwave generator can precisely regulate microwave power to achieve slow, uniform heating. This prevents issues such as cracking or deformation caused by excessive temperatures or rapid heating rates.

High Stability

Solid-state microwave generator exhibit exceptional stability. Based on semiconductor technology with relatively simple internal structures, they lack the wear-prone components found in magnetrons. This enables highly stable microwave power and frequency output during prolonged operation.

In continuous microwave sintering production, stability is paramount. Consistent microwave output ensures repeatability and uniformity in the sintering process, thereby enhancing product quality and yield rates. For instance, in the mass production of ceramic cutting tools, employing solid-state microwave generator guarantees that each tool undergoes sintering under identical microwave conditions, ensuring stable tool performance and quality.