Application Overview

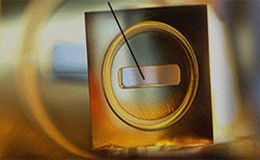

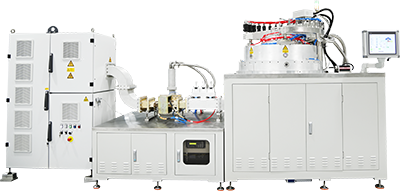

MPCVD diamond coating is a diamond coating produced via microwave plasma chemical vapour deposition (MPCVD). Unlike other types of diamond abrasives, MPCVD diamond coatings are manufactured under controlled conditions, enabling more consistent quality and performance. Consequently, MPCVD diamond coatings are typically employed in precision-critical applications, such as cutting sensitive materials or finishing delicate surfaces. Furthermore, MPCVD diamond coatings can be utilised for numerous other purposes, including grinding, lapping, and polishing.

Application Details

Microwave Plasma Chemical Vapour Deposition (MPCVD) for diamond coating represents an advanced material processing technique that deposits a thin diamond film onto substrate surfaces through chemical reactions. Coatings produced by this method not only possess the superior physicochemical properties of diamond but also enhance the performance of the underlying substrate. In recent years, MPCVD diamond coatings have found extensive application across multiple sectors.

1. Abrasives and Grinding Tools

Within the abrasives industry, MPCVD diamond coatings are extensively employed in the manufacture of abrasive grains, grinding wheels, and other grinding tools. Diamond coatings enhance the grinding capacity and durability of abrasive tools. Compared to traditional abrasive materials, MPCVD diamond coatings not only improve grinding efficiency but also extend tool service life. Consequently, MPCVD diamond abrasives are increasingly becoming a preferred choice for processing metals, glass, ceramics, and other materials.

2. Cutting Tools

MPCVD diamond coatings offer significant advantages in cutting tool manufacturing. As diamond is the hardest known material, its coating enhances tool wear resistance and service life. Under high-temperature and high-pressure conditions, diamond coatings also exhibit excellent thermal stability. This enables them to maintain cutting performance and surface quality when machining high-hardness materials such as titanium alloys and cemented carbides. Furthermore, MPCVD diamond coatings reduce friction during cutting, thereby improving machining efficiency and surface finish.

1. Abrasives and Grinding Tools

Within the abrasives industry, MPCVD diamond coatings are extensively employed in the manufacture of abrasive grains, grinding wheels, and other grinding tools. Diamond coatings enhance the grinding capacity and durability of abrasive tools. Compared to traditional abrasive materials, MPCVD diamond coatings not only improve grinding efficiency but also extend tool service life. Consequently, MPCVD diamond abrasives are increasingly becoming a preferred choice for processing metals, glass, ceramics, and other materials.

2. Cutting Tools

MPCVD diamond coatings offer significant advantages in cutting tool manufacturing. As diamond is the hardest known material, its coating enhances tool wear resistance and service life. Under high-temperature and high-pressure conditions, diamond coatings also exhibit excellent thermal stability. This enables them to maintain cutting performance and surface quality when machining high-hardness materials such as titanium alloys and cemented carbides. Furthermore, MPCVD diamond coatings reduce friction during cutting, thereby improving machining efficiency and surface finish.